Bell Schweiz AG standardises delivery processes and optimises container cycles

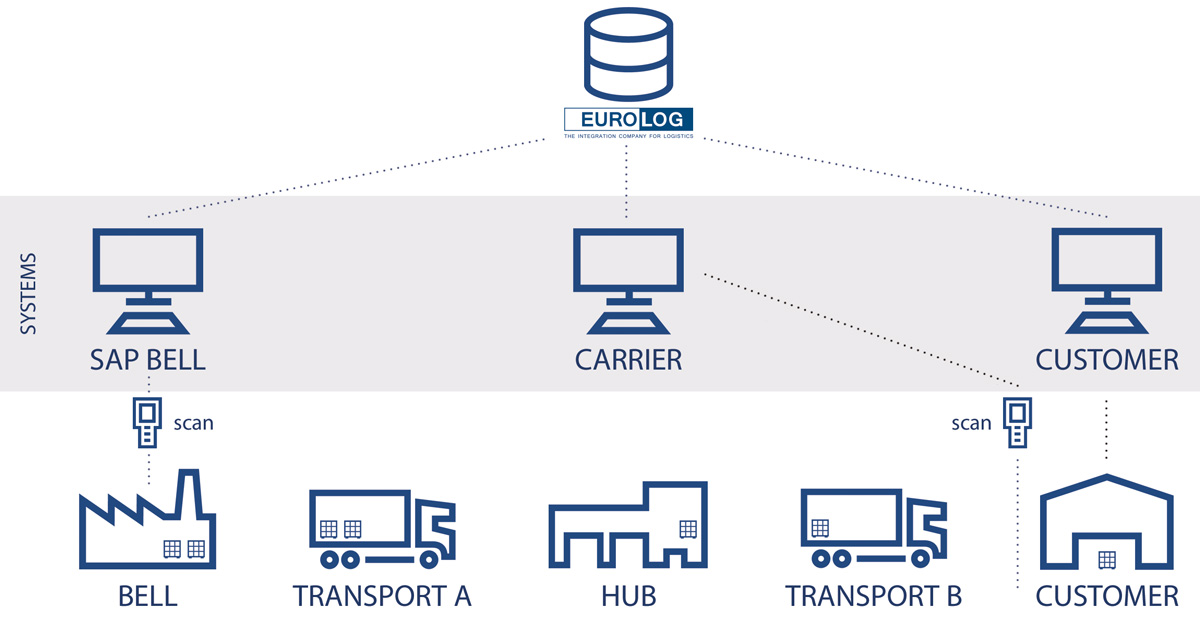

Thanks to the IT solutions of Euro Log, Bell has standardised, digital detection and logistics processes at its command. The SCM platform from Euro Log provides a foundation for communication and data for all process participants in real time.

Initial situation at Bell

The Swiss meat processor Bell supplies around 1,500 customers from wholesalers to butchers from eleven plants. The logistical complexity therefore lies in the acquisition of the material handling equipment (MHE) for different customer systems, the allocation of deliveries to the various customer systems and the consolidation of deliveries to six handling platforms.

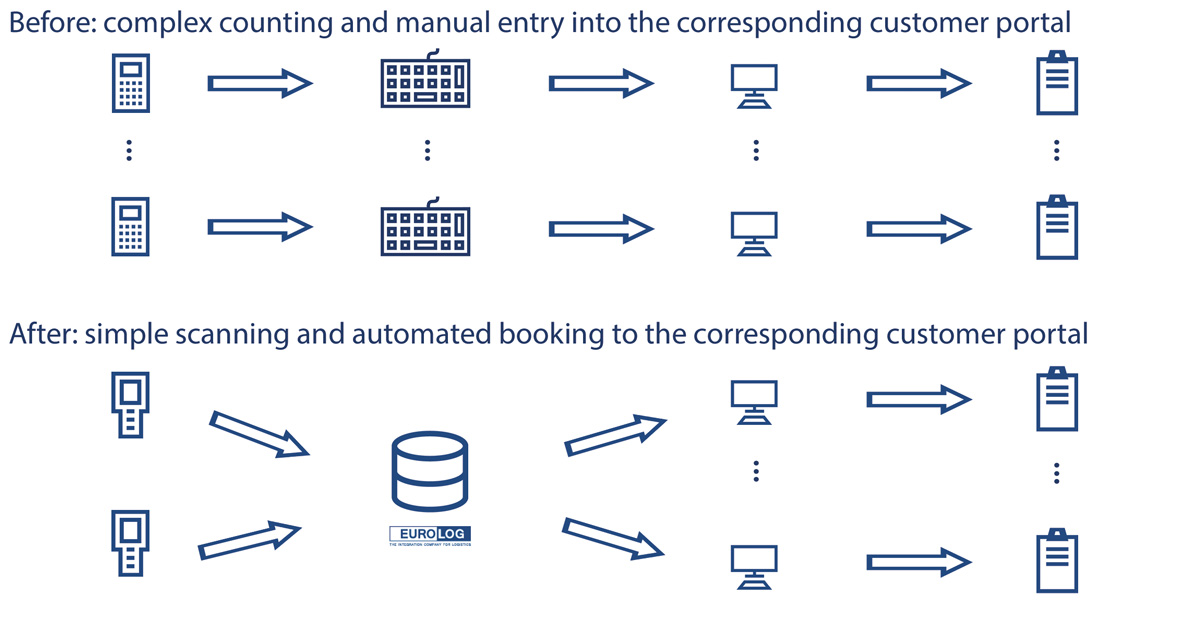

Standardised digital assessment

Instead of manually counting and recording the necessary MHE, employees at the goods outward scan each unit used in the fresh product area. The master data stored in the system automatically assign the data to the corresponding customer system. This reduces the effort and the potential for errors upon recording the entries at goods outward. With a simple scan the data is transferred to the corresponding customer system and the correct MHE delivery notes are automatically created.

The SCM platform from Euro Log provides a foundation for communication and data in real time

Following collection, the ERP-SAP system at Bell Schweiz AG consolidates and sends the data to the SCM platform. Each of Bell's 1,500 customers is assigned to one of Bell's six transshipment platforms. Depending on the customer's order, one or more of the eleven plants deliver the ordered goods to the respective hub. Here, due to the route planning, the delivery is packed, to include packing of the MHE.

Upon delivery, the carrier scans the SSC code on the consignee label on the MHE container and records any deviations from the planned delivery and the MHE preload. He sends the data to the SCM platform. Reference to the proof of delivery documentation enables Bell Schweiz AG to recognise whether and which containers have remained at the transshipment point or with the customer.

Bell has comprehensive insight into the current stock at all times and can track the location and retention time. At a single glance, Bell can identify the stock at each plant and the critical deliveries. In the event of a delay, Bell employees can inform the customer promptly and proactively. Bell also receives automated reports on stocks, transactions, risk factors and account statements for the MHE.

Key elements of the project at a glance

- Simple integration and merging of customer and supplier systems

- Real-time access for all process owners via the SCM platform

- Transparency in the cross-company container cycle

- Automated booking via the SAP/BMS interface

- Container management app for mobile devices

- Reduction of container shrinkage and MHE purchases

EURO-LOG Contact for Bell

Claus Süskind

Head of Sales

EURO-LOG AG

Am Söldnermoos 17

85399 Hallbergmoos-Munich

Phone: +49 811 9595-109

Fax: +49 811 9595-199

E-Mail: c.sueskind@ eurolog.com

eurolog.com

„With the help of EURO-LOG we achieved our goal, transparency over the entire transport network, in a very short time. Within one year a ROI was ensured.“

Armin Bergbauer, CIO Germany & Senior Director Application Development Europe,Ingram Micro Distribution GmbH

„The combination of container management and app helped us to make our container management processes simpler and shorter.“

Thomas Kraft, Managing Director Logistics, HYDAC Verwaltungs GmbH

„By integrating ONE TRACK into our website, our customers can be specifically informed about a shipping via e-mail alert.“

Hondo Santos, Director Logistics, Balluff GmbH

„The smartphones are much more cost-effective than our previous hardware. In addition, the app has been well-received by our drivers since it is very intuitive and easy to use with the clearly understandable icons.“

Frank Reichert, Branch Manager, Beeger Internationale Stückgut Logistik GmbH

„Mobile Track enabled us to reduce our costs and save on the time and effort of our employees.“

Roland Gigl, former Managing Director, GS Frachtlogistik GmbH

Choose by solutions or industries

Whith the smartphone app Mobile Track can drivers scan package units and the receipt of shipments can be acknowledged by customers via a signature on the smartphone.

GS Frachtlogistik saves time and money with logistics apps

HYDAC achieves a company-wide view of the physical inventories of in-house and customer containers.

Comprehensive container management at HYDAC

Digitalising the logistics chain creates the transparency needed to elevate cooperation between process partners to the next level.

Connect. Collaborate. Control. EUROLOG SCM Platform

EURO-LOG AG - AM SÖLDNERMOOS 17 - D-85399 HALLBERGMOOS - INFO@EUROLOG.COM - PHONE 0049 811 9595-0